Como consecuencia de la amplia variedad de aceros que se utilizan en la fabricación de carrocerías de automóviles, es necesario dividirlos en grupos. El criterio para esa división puede ser en función de su límite elástico, límite de rotura, valores mecánicos o incluso alargamiento. En este caso el criterio que se ha elegido para clasificarlos ha sido en función de su límite elástico, resultando los siguientes grupos:

- Aceros Convencionales.

- Aceros de Alta Resistencia.

- Aceros de Muy Alta Resistencia.

- Aceros de Ultra Alta Resistencia.

Acero Convencional (no estructural)

El acero convencional es un acero

dulce no aleado, laminado en frío y con un bajo contenido en carbono.

Este reducido contenido en carbono le proporciona unas buenas

características para el trabajo de deformación en prensas, pero por el

contrario su límiteelástico es demasiado bajo, por lo que se necesitan mayores espesores para soportar los esfuerzos a los que se someten las distintas piezas, y además en los paneles

exteriores se producen abolladuras con facilidad.

Empleo:

Su bajo límite elástico lo convierte en un material para usar en piezas con baja responsabilidad estructural (aletas, paneles de puertas, portones traseros, etc).

Aceros de Alta Resistencia

Estos aceros se clasifican en tres tipos en función del mecanismo de endurecimiento que se usa para aumentar su resistencia.

- Aceros Bake-Hardening

Empleo:

Estos aceros están destinados a piezas de panelería exterior (puertas, capós, portones, aletas delanteras y techo) y piezas estructurales para el automóvil (bastidores inferiores, refuerzos y travesaños).

Reparación:

Durante el reconformado se deberá realizar un mayor esfuerzo, que si se tratara de una

pieza fabricada con acero convencional, debido a un límite elástico más elevado. Mientras que su aptitud a la soldadura es buena sea cual sea el método utilizado, al tener poca aleación.

- Aceros Microaleados o Aceros ALE

Empleo:

Estos aceros se destinan sobre todo para piezas interiores de la estructura que requieren una elevada resistencia a la fatiga, como por ejemplo los refuerzos de la suspensión, o refuerzos interiores. También se pueden encontrar en largueros y travesaños.

Reparación:

Poseen una buena aptitud a la soldadura con cualquier procedimiento debido a su bajo

contenido de elementos de aleación, mientras que en el proceso de reconformado se deberán realizar esfuerzos mayores como consecuencia de su mayor límite elástico

en comparación con los aceros convencionales.

- Aceros Refosforados o Aceros Aleados al Fósforo

Empleo:

Las piezas fabricadas con esta clase de acero se destinan a usos múltiples, como piezas de estructuras o refuerzos que están sometidas a fatiga, o piezas que deben intervenir en las colisiones como son largueros, travesaños o refuerzos de pilares.

Reparación:

Siguiendo la tónica de los Aceros “Bake Hardening” y de los Aceros Microaleados el

proceso de reconformado requiere de la aplicación de unas fuerzas mayores para recuperar la geometría inicial de la pieza. Con respecto al proceso de soldadura reseñar que cualquier procedimiento es apto debido a su bajo contenido en elementos aleantes.

Hot-dip galvanised dual-phase steels. (Aceros muy alta y ultra alta res.)

Multiphase steel grades with even higher strength values are referred to as Advanced High Strength Steels (AHSS) owing to their excellent prospects. In the family of multiphase steels which are listed in the preliminary standard DIN EN 10336 (with hot-dip coated and/or electrogalvanised surface), dual-phase steels are the most important group.

Their extensive use was predicted for the first time in the late 1990s within the framework of the ULSAB projects and then documented, among others, in "Atlas", a joint project by Salzgitter and Karman.

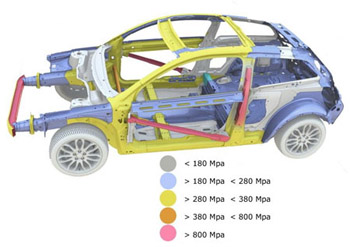

Figure 1: ULSAB study, portion of high-strength and ultrahigh-strength steels.

The reason for the increasing possible applications with OEMs

is that the vehicle weight is to be reduced by using thinner sheets and

that passenger safety is to be ensured at the same time.

The designation of dual-phase steel is derived from its microstructure consisting of a ferritic (soft) matrix with a mainly martensitic second phase (increasing the strength) embedded like islands. This "soft-hard" combination gives the dual-phase steel a relatively low yield strength with high tensile strength which is positive for forming processes. This favourable ratio of mechanical characteristics points towards correspondingly good ductility, which is essential especially for complex components.

Figure 2 provides a schematic view of a microstructure.

The designation of dual-phase steel is derived from its microstructure consisting of a ferritic (soft) matrix with a mainly martensitic second phase (increasing the strength) embedded like islands. This "soft-hard" combination gives the dual-phase steel a relatively low yield strength with high tensile strength which is positive for forming processes. This favourable ratio of mechanical characteristics points towards correspondingly good ductility, which is essential especially for complex components.

Figure 2 provides a schematic view of a microstructure.

Figure 2: Dual-phase structure, schematic view

This new family of steel grades opens up new applications for

structural parts to car manufacturers and their suppliers (e.g. side

members, crossmembers, columns, tunnels).

Even applications in the car skin (doors) are

perfectly conceivable, just as the use of these materials for so-called

machine-ready tubes that may also be used in car manufacture, possibly

following a hydroforming process.

High energy absorption in case of a possible crash takes the safety aspects into consideration.

Figure 3: Tunnel made of HCT600XD+Z from Salzgitter

Processing dual-phase steels in the forging press departments

of car manufacturers or their suppliers requires only slight

modifications as compared to ultrahigh-strength microalloyed steels that

have been used for a long time.

As compared with the latter, dual-phase steels stand out for their considerably higher tensile strength, their bake hardening (endurecimiento por recocido) capability and their high energy absorption capability in case of a car crash.

Since the FV2 (FV = German abbr. for hot-dip galvanising line) was commissioned, Salzgitter Flachstahl is in a good position for developing and producing corresponding steel grades. Hot-dip galvanised dual-phase steels can be produced as described below.

As compared with the latter, dual-phase steels stand out for their considerably higher tensile strength, their bake hardening (endurecimiento por recocido) capability and their high energy absorption capability in case of a car crash.

Since the FV2 (FV = German abbr. for hot-dip galvanising line) was commissioned, Salzgitter Flachstahl is in a good position for developing and producing corresponding steel grades. Hot-dip galvanised dual-phase steels can be produced as described below.

The strength-increasing phases of a martensitic

nature (cf. Figure 2) are created by quenching after annealing the

cold-rolled strip before feeding it into the zinc pot.

If partial hardening of the microstructure occurred

at an earlier stage, this would create problems in the downstream

process steps owing to the high material strength. This is why the

upstream hot-rolling mill produces a relatively soft microstructure

without martensite.

The last process step in dual-phase steel production, i.e. hot-dip galvanising, requires particular process control efforts.

This step produces hot-dip galvanised ultrahigh-strength strips which

will allow meeting the increasing requirements in car engineering

regarding weight reductions and passenger safety in the future.An intense cooperation between Salzgitter Flachstahl and Salzgitter Mannesmann Forschung in the meantime resulted in a clear expansion of the available product range. The grades HCT450X to HCT600X are delivered for series production and sample deliveries for the HCT800X have been made.

Aceros HSS aleados con boro (BOR)

Piezas estructurales de la carroceria.

Interesante: cortando pilares de aceros HSS

Excarcelación bomberos.

No hay comentarios:

Publicar un comentario